Sailboat Diesel Engine

Cooling System

The subject of the sailboat diesel engine cooling system came up recently when I mentioned that you should look at your cooler and change the coolant. He had a Yanmar diesel installed, and the condition of the coolant that came out is telling. After flushing, finding sludge accumulations and then adding the new coolant he should be good for a couple of years. Change intervals vary from annually to bi-annually and some base it on running hours.

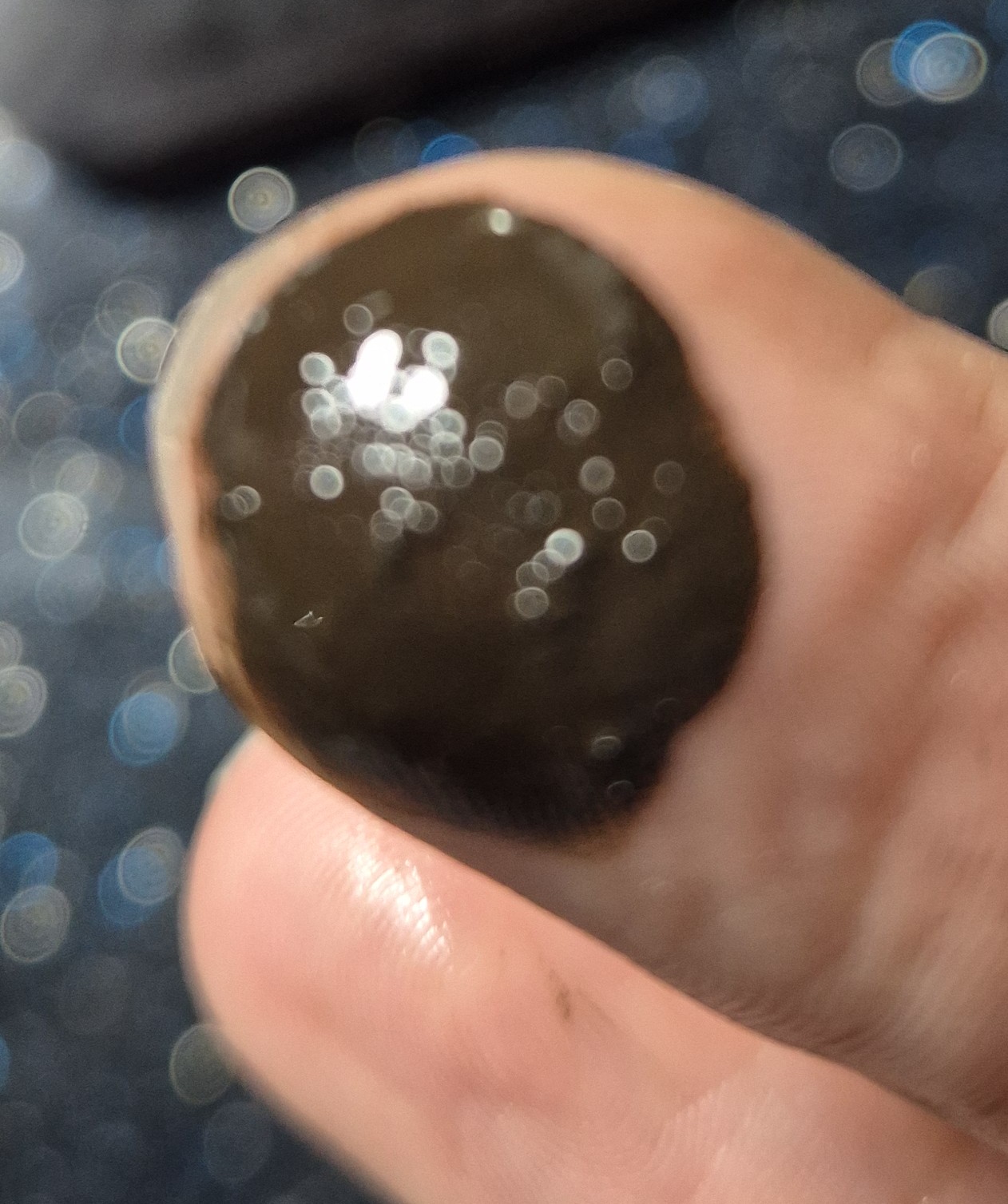

The common cause of engine overheating is usually seawater related, such as clogged strainers, or intakes clogged with plastic, or the familiar seawater pump impeller failure. I once had a high engine temperature issue on a previous boat. After a major big ship mid-channel transit emergency, and anchoring I discovered that the heat exchanger tubes were caked in fine silt from the very brown, silted river we were transiting in Europe. The image below shows sludge from a heat exchanger after it was drained and refilled with new coolant.

Sailboat Diesel

Engine Cooling System

A quick systems review, marine diesel engines have a heat exchanger with a closed-circuit freshwater (FW) cooling system. The freshwater cooling system uses a pump that circulates water through the various cooling engine galleries, oil coolers and so in from the heat exchanger and back again. This carries way heat from the engine and maintains a constant and stable engine temperature.

The engine freshwater cooling system must remain saltwater contamination free to prevent corrosion or formation of sludge and scale that may impede coolant flow or block coolers. this reduces heat transfer rates by coating engine block water passages with insulating scale buildup. This will result in gradual overheating, with all the damage that comes from it.

Sailboat Diesel

Engine Coolants

Most engine now specify coolant types or the concentration of additives required, as it is more than just simple glycol. A number of additives are available to improve the performance of engine coolants. Engine coolants may contain sulfates, chlorides, dissolved solids, and calcium. Coolants should have an antifreeze additive to prevent freezing and engine damage in cold climates. Most ethylene glycol–based antifreeze solutions contain the required inhibitors for normal operation. Corrosion inhibitors are water-soluble chemical compounds that protect the internal engine block metallic surfaces against corrosion. These chemical compounds can include borates, chromates, and nitrites. As a note soluble oil should not be used as a corrosion inhibitor. Check your engine manual. The image below shows coolant that had broken down and stratified in the heat exchanger after it was drained and then refilled with new coolant.

Engine

Coolant Additive Degradation

There is some misinformation about the shelf life of coolants. Engine coolant additives degrade over time due to several factors:

- Oxidation: Exposure to oxygen leads to the formation of acids, sludge, and contaminants, reducing coolant effectiveness.

- Temperature fluctuations: High engine temperatures accelerate chemical breakdown, weakening the coolant’s protective properties.

- Contamination: Dirt, debris, and engine oil leaks disrupt the coolant’s chemical balance, affecting heat transfer.

- Corrosion: Contact with metals like aluminum, steel, and copper can lead to rust, scale, and deposits, impairing the cooling system efficiency.

- Water quality: Poor-quality water in the coolant mixture can destabilize additives, reducing their lifespan. I use ready mixed from Volvo for my own engine, so I know its correct.

- The Marine Electrical and Electronics Bible 4th Edition. A lot about marine diesel engines. You can buy a copy here.

Engine

Coolant Additive Degradation

If coolant additives degrade excessively, several serious issues can arise:

- Overheating: The coolant loses its ability to dissipate heat effectively, leading to engine overheating.

- Reduced lubrication: Some additives help lubricate the water pump and other components. When they break down, friction increases, potentially causing premature wear.

- Corrosion damage: Degraded coolant can become acidic, leading to rust and deposits in the cooling system, which can clog passages and reduce efficiency.

- Formation of sludge: Contaminants and degraded additives can create sludge, restricting coolant flow and reducing heat transfer

Engine

Coolant Additive Degradation

Signs that your engine coolant is degrading:

- Discoloration: Fresh coolant is usually bright in colour. If it appears murky, brown, or rusty, it may be breaking down.

- Sludge accumulation: Thick sludge in the coolant reservoir indicates contamination and degradation. Open the drain cock or point and see what comes out.

- Overheating: If your engine temperature is increasing more than usual, degraded coolant may be failing to properly regulate the heat.

- Floating particles: Small debris or particles in the coolant can indicate a breakdown of the coolant additives.

Engine

Coolant Explainer

Why the different colours? The blue and pink coolant mixes typically indicate different chemical formulations and intended use. Check your manual for the correct additive or coolant mix.

Pink coolant is usually based on Hybrid Organic Acid Technology (HOAT). It combines organic acids with some silicates or phosphates to protect aluminum and other metals. It is commonly used in European and some American diesel engines and is designed for longer service intervals.

Blue coolant refers to Phosphate Organic Acid Technology (POAT) or similar formulations. It is often found in Asian diesel engines and is optimized for aluminum components, offering excellent corrosion protection and thermal stability. Be warned, mixing them can impact performance and damage an engine. Different additives can react poorly together, potentially forming sludge or reducing corrosion protection.

About System Cleaners. There are flushing fluids available. One well-known system cleaner is Sea Flush, which is a patented formulation for cleaning and flushing engine, generator, and air-conditioning heat exchangers, oil coolers, and other system components. Descalers are usually caustic, so care must be taken. Sailboat diesel engine cooling systems need to be maintained.