Marine Electrical Wire Connectors

Marine electrical wire connectors are a big cause of failures. When it comes to connecting wires, soldering is often hailed as the gold standard for creating strong, reliable connections. However, many people have varying opinions on the best process for making electrical connections. There are alternative methods for those who prefer not to solder. In this guide, we'll explore various ways to connect wires without soldering, briefly discuss the safety issues associated with each method, and ultimately explain why soldering stands out as the best option.

Connections fail for many reasons. The main reason is the wrong method for the application. The second is they are not installed properly. Boats suffer from vibration and can work loose over time. Another issue is that connections are not always physically supported to prevent this. So, should you crimp or should you solder or use another format such as wire connectors? Why there is even an argument over this point is somewhat baffling.

Marine Electrical Wire Connectors

The choices are many, you can use those chocolate block terminals, you can use crimp butt type connectors, then on equipment there are bullet type connectors and also spade type connectors. The last main one is the ring connector which is always my choice at switchboards. Another is the BP screw connector. More recently there the very excellent Wago spring connectors. Absolutely do not use those screw connectors or nuts, which are against all rules and I wouldn’t use them in a domestic application let alone a boat scenario. But they are still getting used.

Marine Electrical Wire Connectors

This method is by far the most common. You remove insulation from each end of the wires to be joined. You select an insulated crimp connector such as butt type of the required cable capacity, either red, blue or yellow. Then you use a ratchet crimping tool to compress the crimp terminal around the inserted cable. Unlike soldered connections where solder wicks partially into the conductor strands and creates stiffness, the conductor strands remain flexible into the connector ferrule. The mechanical compression captures the cable. Quality crimps need a good quality crimping tool set for the correct compression as most are adjustable. Done use those cheap squeeze type crimpers, they are useless. For my professional activities I used a standard ratchet crimping tool for those red, blue and yellow insulated crimp connectors. Then I have a set of ratchet crimpers for the next range of cable terminals and finally I have the heavy-duty crimpers for crimps that range from 16mm up to 50mm such as primary battery terminals and so on. When you crimp uninsulated terminals you slide heat shrink tubing onto the cable and then when crimped move it over the crimp barrel and heat. There is a reason why soldered heavy duty terminals are no longer used as crimp connections in heavy duty high current applications handle vibration and mechanical stress much better. For more useful information on boat wiring get the latest 4th Edition of my book The Marine Electrical and Electronics Bible.

Marine Electrical Wire Connectors - Wago

I have started using these on every installation. These are compact wiring splices that utilize a lever mechanism, pull up the lever, insert the wire end and push it down again, The spring Cage Clamp® tension holds the conductor securely. They are designed to handle solid, stranded and find stranded conductors in the range 0.14 to 4mm². They are vibration proof and maintenance free. They are orange and insulated with a transparent cover for easy inspection. There are models for larger cables up to 6mm². The standard units come in 2, 3, 4 and 5 terminal models which works well for joining cables and carrier mounts are available. For areas like above bilge wells they also have Gel boxes to place around the splices which are removable. They are 450 V Rated and surge voltage rated at 4 kV with rated current of 32 A. Ambient temperature rating is +85°C and continuous operating temperature is 105°C. They are quality made in Germany (and not China!). I have switched over to using these on circuit terminations.

Marine Electrical Wire Connectors

The very common chocolate block style insulated PVC terminal block strips are used everywhere. Simple cut off the number you require and using an appropriate sized screwdriver insert wires each side and tighten. When of the advantages is you can sometimes insert multiple cables into each terminal, and the terminal strips come in several cable capacity sizes. The disadvantages are trying to hold a terminal while inserting a cable and maintaining it until you tighten the terminal screw can be often awkward on a boat. Another issue when using a block with multiple cables is the risk of a stray conductor strand remaining outside the terminal ferrule and shorting across to an adjacent terminal which is a common fault area. As these blocks are essentially domestic quality the plated terminals often corrode is salt air. The advantage is that it allows easy and quick circuit disconnection when fault finding.

Marine Electrical Wire Connectors

I frequently encounter wiring joints where someone has simply stripped off the insulation and twisted the strands together and wrapped some electrical tape around the joint. Sure it is quick in a difficult situation but like most temporary fixes they somehow become permanent until they ultimately fail. Usually. the twisted conductor strands unravel and a high resistance joint develops, with intermittent circuit failure and with high resistance comes over heating and worst cause a fire

Marine Electrical Wire Connectors

I have written extensively about this on another page. Besides being open to poor quality electrical connections. They are difficult to get right in a boat environment, require skill, require tools and are time intensive. They require insulation with heat shrink. The worst drawback is that joints are inaccessible for connection and disconnection, the joint and adjacent cable becomes stiff and not resilient to vibration. They are also even if done properly no more electrically superior than crimped connections. One issue frequently raised is the high probability of conductor strands being annealed during the heating process. There seems to be a polarized range of opinions as to the merits of solder over crimped connections. For those who think applying solder to a crimped connection enhances the integrity of the joint, think again. In general this weakens and stiffens the cable termination. However, I have seen people crimp a ring connector and allow a small amount of the wire to protrude out at the ring section. Then a small dab of solder is applied at the end which secures the cable and gives 100% conductivity however it takes skill not over heat the connector insulation or wick up the conductor strands.

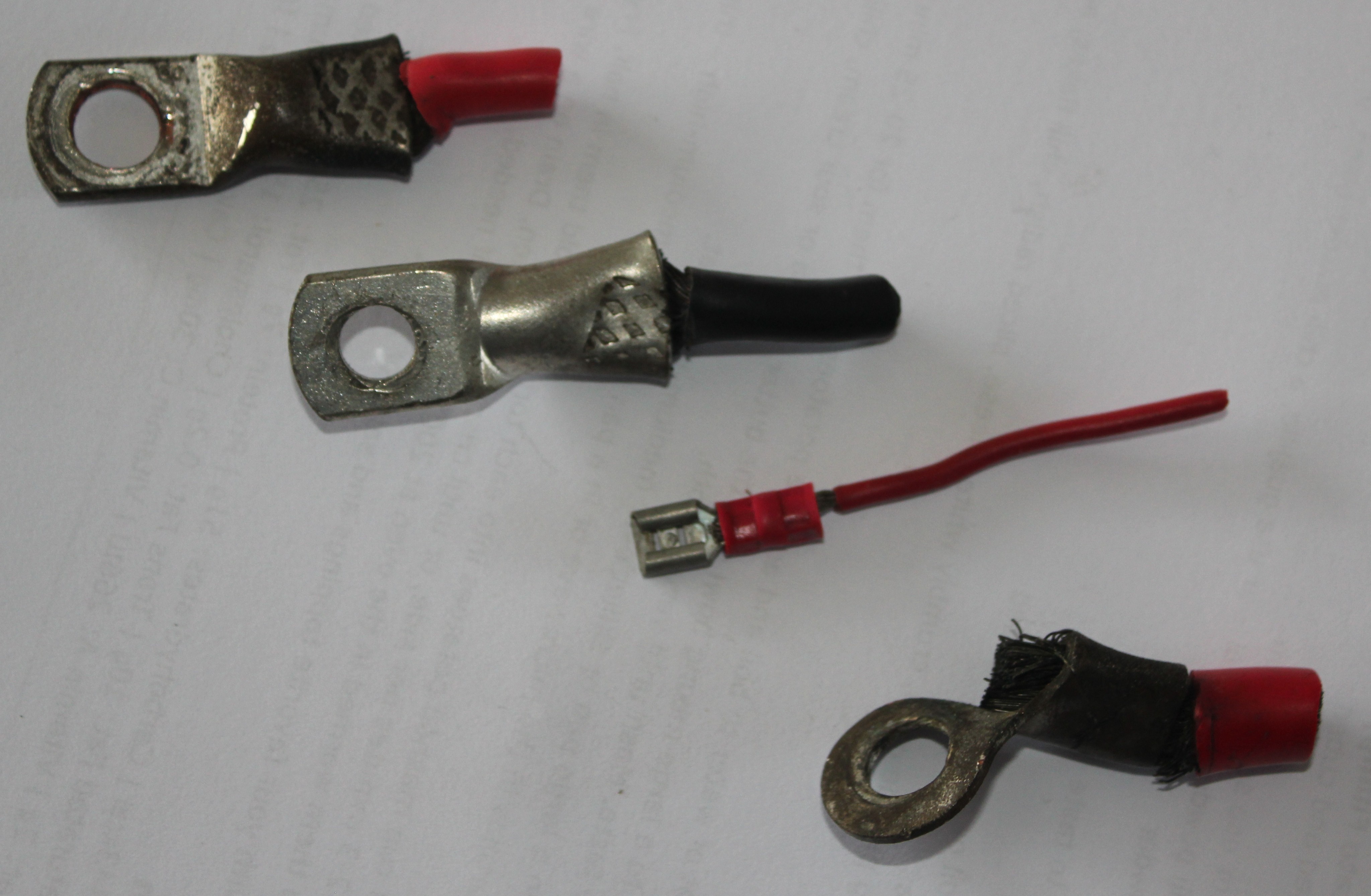

The image below shows an assortment of sub standard and improperly terminated connectors removed from recent boats I have worked on.

Marine electrical

wire connectors - Crimping

Whether aviation, maritime, defence, aerospace, medical, industrial and automotive, crimping is the preferred method of cable connection It is fast, it is consistent and suits high vibration environments. There are industry specifications and standards that include MIL_SPEC and WHMA-A-620. The latter is the accepted standard for cable and wireless assemblies from the Wiring Harness Manufacturers Association. The Requirements and Acceptance for Cable and Wire Harness Assemblies prescribes the practices and requirements for the manufacturing of cable, wire, and harness assemblies, and describes materials, methods, tests, and acceptability criteria for producing crimped, mechanically secured, and soldered interconnections. More recent revisions include soldering requirements with IPC J-STD-001, Requirements for Soldered Electrical and Electronic Assemblies. The IPC/WHMA-A-620 standards define the acceptance criteria for cable, wire, and harness assemblies, and incorporate crimping, soldering, splicing, and mechanical fastening. The standards have 3 distinct categories based on the criticality of the application.

Class 1 (General Electronics): This prioritizes functionality above longevity, and includes applications such as domestic household appliances, such as your washing machine or dishwasher.

Class 2 (Dedicated Service): This balances durability and performance for equipment used within industrial and commercial environments

Class 3 (High-Performance): This category mandates zero failures in mission-critical systems, for example aviation, aerospace, medical devices and so on. I include small boat electrical systems in this category

Marine electrical

wire connectors - Crimping

So that is the case for each type of connector, the pros and cons, and professionally the drivers are ease of connection and disconnection, and the electrical integrity of the connection. When I wire a boat, I do not have any intermediate connections in circuits, with all connections being either at the switch panel or at the device. These are a 100% accessible for troubleshooting as well initial installations. There is always a good loop of cable to allow for ease of connection and there is never strain on any connector. Marine Electrical Wire Connections can be reliable, choose the right method.