12V Marine Electrical

Connectors

12V marine electrical connectors and the comparative advantages of crimped and other connector types with respect to soldered connections are discussed elsewhere. It is worth looking specifically at ring connectors. These are used at the lower current capacity spectrum up to the heavy-duty ones required on engine starting circuit cables, and alternator charging cable as well those powering inverters and anchor winches.

Very few boats have invested in high quality crimp tools. My heavy-duty crimpers are crimp that range from 16mm up to 50mm. When you do crimp these heavy duty uninsulated terminals you must remember to slide the heat shrink tubing onto the cable before your crimp. When crimped move the heat shrink over the crimp barrel and heat.

12V Marine Electrical

Connectors

12V marine electrical connectors are a constant cause of circuit failure and they should be made properly if you wish to maintain reliability. All conductors should be terminated where practicable using crimped connectors or a viable alternative. The most practical and common method of cable connection is the tinned-copper, crimp terminal or connector. These are color coded according to the cable capacity that can be accommodated. These connectors are designed and manufactured according to NEMA standards, and this includes wire pull-out tension tests, and voltage drop tests. Where possible select double crimp type terminals, which should be used in high vibration applications. When crimping, always use a quality ratchet-type crimping tool. And do not use those cheap squeeze crimper types, as they do not adequately compress and capture the cable. I have seen this a lot, people use electrical plier cable cutter section and squeeze them for crimping. This invariably causes failure and the cable pulls out of the connector sleeve. A good quality termination requires two crimps and this is always on the larger cable terminals. Always crimp both the joint and the PVC insulation behind it. Ensure that no cable strands are hanging out. After crimping, give the connector a firm tug to ensure that the crimp is secure.

Ring

Crimp Terminals

These terminals are used on switch panels and related termination strips. They are also used on all major current equipment where screw, stud, bolt and nut are used. They should be used on any equipment subject to vibration, or where accidental dislodgement can be critical, particularly switchboards. Always ensure that the ring is a close fit to the bolt or screw used on the connection, to ensure good electrical contact and frequently I fin they are oversized and have a poor electrical contact. Also consider using spring washers to maintain contact pressure and offer protection against vibration creepage. The larger crimp lugs have the cable size and the diameter of the ring stamped on the upper lug contact surface. Make sure the ring matches the terminal bolt to maximize contact. Also make sure you match the barrel size with the cable diameter. I frequently find oversize barrels are crimped onto undersized cables and this makes a very poor contact and risks high resistance and loosening causes heating and failure. Get a copy of my book The Marine Electrical and Electronics Bible 4th Edition for answers to many questions.

Ring

Crimp Terminals

The image below shows connectors found on a recent job and they are seriously degraded and not fit for purpose. The circuit required rewiring along with new ring connectors. Note the single narrow crimp on the yellow insulation, squeezed with pliers.

Ring

Crimp Terminals

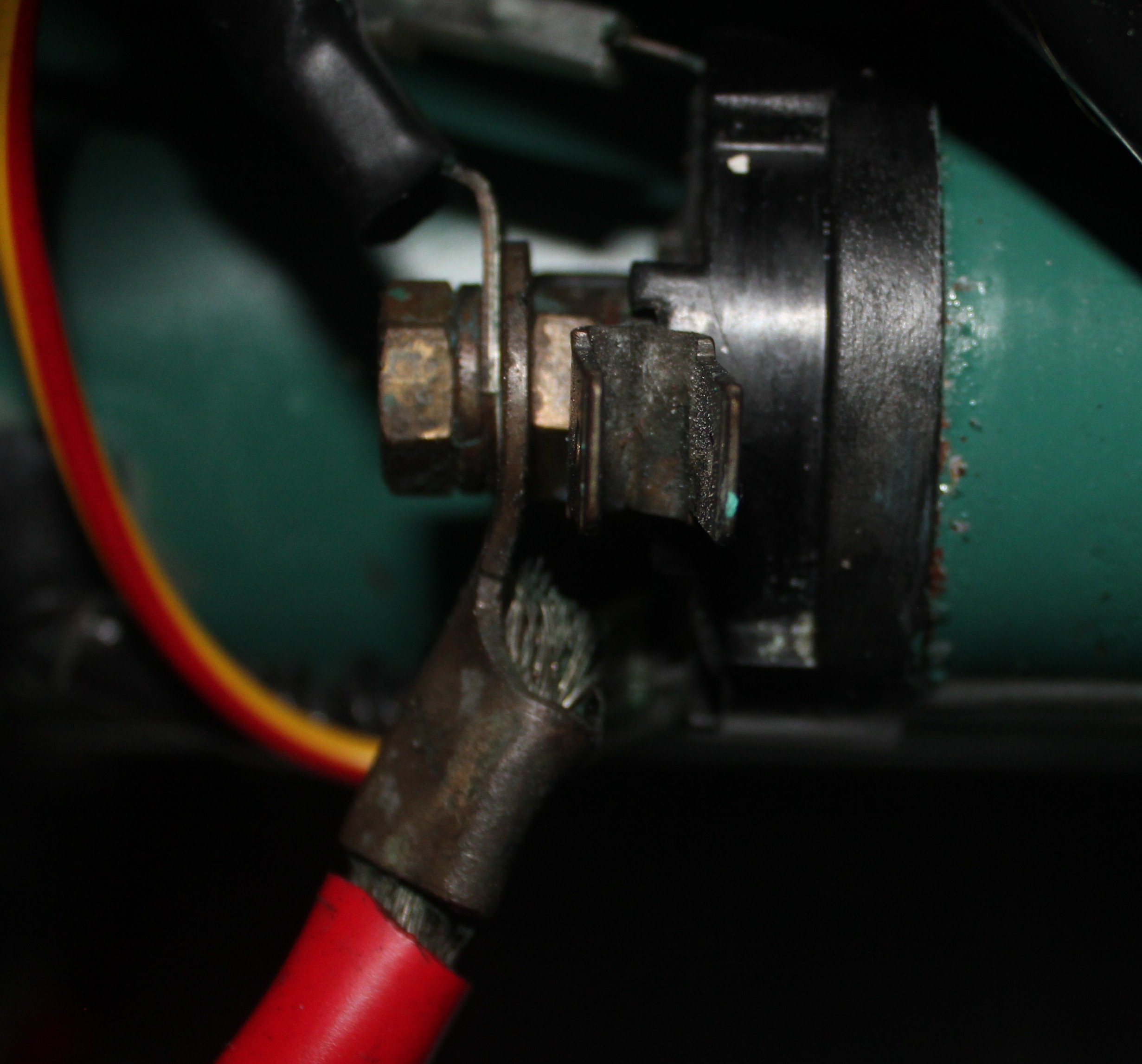

The following image is taken from a starter motor terminal connection and it was found to be in a degraded condition. The terminal was found warm to touch after a start attempt and the whole terminal had high resistance and causing voltage drop when starting. Cleaning the terminal stud and replacing the cable lug resolved this. You have to inspect these regularly as engine mounted connections are subject to vibration.

Ring Crimp Terminals

The following image is from a recent job and shows corroded ring terminals subject to water and corrosion. Crimp terminals are made from tinned copper and they will react when fastened down with say a stainless-steel bolt or not. Galvanic corrosion will take place and you should regularly inspect these connections and if subject to moisture at least spray with WD40 to displace moisture. It may be necessary to regularly replace these when they reach this condition as they are actually high resistance and depending on the application will create a significant voltage drop. As a note if they are not being used on tinned copper conductors the conductor maybe somewhat degraded.

Ring Crimp Terminals

Oxidation occurs when exposed to moisture and it develops a black color. The electrical resistance also increases leading to voltage drop. In some applications when the conductor copper becomes brittle vibration and stress results in breakage. In some cases this travels up significant distance in a wire and the whole wire may require replacement. So couple this with galvanic effects and you have a failure waiting to happen. Ring connectors need to be maintained. While many argue about the merits of using tinned versus untinned wire, the tinned is more resilient to oxidation, and one tip for use in wet areas such as anchor windlass solenoids or foot switches is to ensure that they are coated with WD40 or whatever to apply a small surface layer to the conductor ends that protrude from the crimp terminal barrel. Electrical connections are not install and forget and anything around the engine or a bilge or area that is subject to water or moisture has the capacity to degrade and fail. 12V marine electrical connectors are prone to failure if not installed correctly. Check yours now.