Marine Diesel Injectors

Marine diesel injectors operate by forcing diesel fuel through a precisely machined nozzle at high pressure, creating fine atomization for efficient combustion. A spring-loaded valve opens only when pressure reaches a calibrated threshold, ensuring accurate timing, controlled fuel delivery, and consistent spray patterns essential for proper engine performance. Their timing, atomization, and pattern directly affect power, efficiency, and emissions. Clean, correctly calibrated injectors ensure reliable starting and smooth operation. Wear, contamination, or poor maintenance quickly degrade performance and can cause engine damage.

Marine diesel injectors are a precision-engineered component responsible for metering, atomizing, and delivering fuel into the combustion chamber at very high pressures. The construction and operation rely on the principles of fluid dynamics, materials science, and high-pressure hydraulic control. Although injector designs vary among mechanical, common-rail, and unit-injector systems, all share a set of critical architectural and functional features

Marine Diesel Injectors - Construction

A modern injector, especially in common-rail diesel systems, is typically built from multiple high-strength metallic components designed to withstand peak pressures that often exceed 1,800–2,500 bar, and in advanced systems even surpass 3,000 bar. Key structural elements include the main body. The main injector body is machined from alloy steel with tight dimensional tolerances. Internal passages are honed to ensure precise hydraulic characteristics. The body houses the nozzle assembly, control valve mechanism, fuel inlet port, and electrical actuator (for electronically controlled injectors).

Nozzle Assembly. The nozzle comprises two principal parts.

Nozzle body. A hardened steel housing containing fuel passages that lead to the sac (a small volume that feeds the orifices) and the multiple precision-drilled spray holes. Holes are often produced via laser drilling or EDM (electrical discharge machining) to achieve micrometer level accuracy.

Nozzle needle (needle valve). A finely machined needle that seats against a conical seat inside the nozzle body. The vertical movement regulates the opening and closing of the fuel orifices. The needle must maintain extremely small clearances, typically 2–5 micrometers to minimize leakage while allowing smooth motion.

Actuation Mechanism. Depending on the injector type, actuation can be one of the following:

Mechanical (cam-driven): A rocker or pushrod depresses a plunger.

Hydraulic electronic: A solenoid or piezoelectric actuator operates a control valve.

Piezoelectric: Stack actuators provide very rapid needle lift and highly precise fuel metering.

Control Valve System. Modern fuel injectors include a high-speed control valve either a solenoid-operated poppet valve or a piezo-driven servo valve. The control valve directs high-pressure fuel to one side of the needle or allows pressure to vent to a return line, creating a pressure differential that lifts the needle.

High-Pressure Fuel Passages. Fuel flows from the rail (or pump) through carefully calibrated channels in the injector body. These passages are designed to minimize pressure losses and cavitation. Internal check valves or dampers may be incorporated to stabilize pressure waves.

Seals and Washers. Copper or steel sealing washers isolate the combustion chamber. Internal seals, such as high-temperature elastomers or metal-to-metal precision fits, prevent leakage under extreme conditions.

Marine Diesel Injectors - Design Principles

Injector design follows several engineering principles:

Hydraulic Pressure Amplification and Control. The injector uses high rail pressure and controlled hydraulic forces to move the needle. Surfaces are engineered to achieve predictable differential pressures. The pressure drop across orifices is finely tuned for optimal atomization.

Atomization and Spray Formation. Spray-hole geometry, diameter, length-to-diameter ratio, inlet rounding, and hole angle—governs droplet size and penetration. Diesel injectors are designed to produce highly atomized sprays with Sauter Mean Diameters (SMD) of 10–20 micrometers. Multi-hole nozzles ensure distribution that matches combustion chamber swirl and piston-crown geometry.

Material Properties. Injector components must endure high cyclic stresses, corrosive fuels and additives, temperatures exceeding 300°C in the nozzle tip and wear from high-velocity micro-flows. Alloy steels, coatings (chromium nitride, DLC or diamond-like carbon), and surface treatments (carburizing, nitriding) extend component life.

Thermal Expansion Control. Clearances must remain correct across a wide temperature range. Metal selection and precision fits are engineered so that the needle does not seize or leak excessively as temperatures rise.

High-Speed Electromechanical Dynamics. Piezo injectors rely on rapid actuator response, often <100 microseconds. The mass of moving parts is minimized, and control-valve hydrodynamics are tuned to avoid oscillation and maximize repeatability.

Cavitation Management. Flow paths and inlet radii are designed to reduce cavitation, which erodes nozzle surfaces. Controlled cavitation, however, may be intentionally used in some designs to enhance atomization.

Marine Diesel Injectors - Operation Principles

The injector’s operation can be summarized in several phases:

Fuel Pressurization. In common-rail systems, a high-pressure pump maintains a constant fuel pressure in the rail. Each injector receives this pressurized fuel at its inlet. The injector itself does not create pressure; it modulates it.

Control Valve Activation. When the ECU commands injection. A solenoid is energized, or a piezo stack expands. The actuator shifts the control valve. This change opens a vent path or modifies hydraulic pressure on the needle’s control chamber. A pressure imbalance occurs between the upper and lower surfaces of the needle.

Needle Lift. As the pressure on the needle seat exceeds the downward hydraulic force plus spring preload, the needle lifts. This opens the nozzle orifices, allowing high-pressure fuel to spray into the combustion chamber.

Fuel Injection and Atomization. Fuel traveling through the orifices at extremely high pressure undergoes turbulence and breakup, forming a fine mist. Injection may occur in multiple pulses of Pilot injection, Main injection, Post injection. These control noise, NOx emissions, and particulate formation.

Needle Closure. When the control valve de-energizes, pressure equalizes in the control chamber. The return spring forces the needle downward, closing the nozzle. High precision ensures that closure is rapid and that the end of injection is clean, minimizing dribble.

Return and Cooling Flows. Some fuel is routed through return circuits for cooling and lubrication of injector internals. This keeps temperatures stable and removes contaminants.

Marine Diesel Injectors - Injector Removal

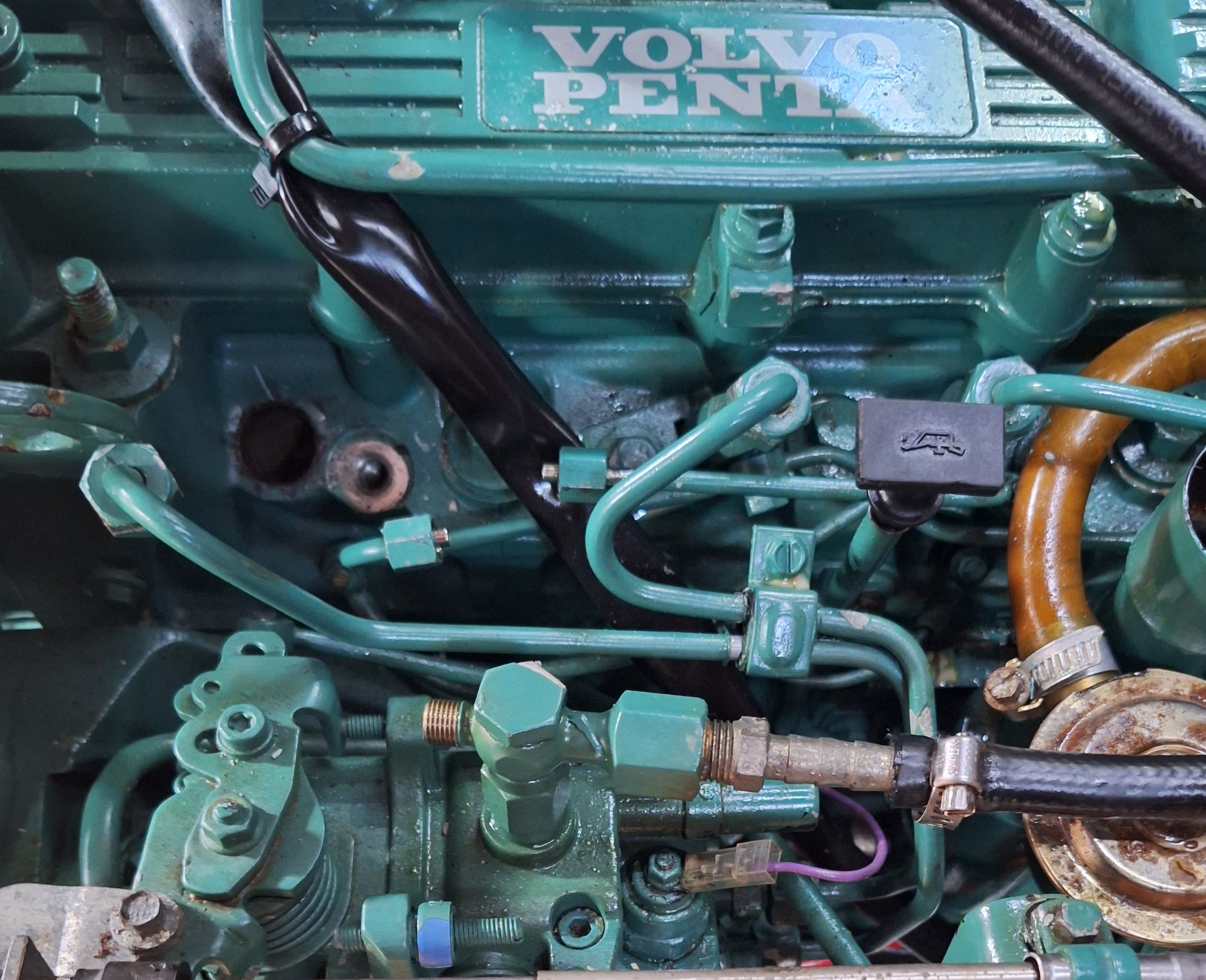

Every engine is different and on my own boat when I recently removed injectors for inspection and subsequent reconditioning I found that it was difficult to access retaining bolts and even loosen the injectors and extract them, follow these basic steps. Removing fuel injectors from a small marine diesel engine requires controlled depressurization and careful handling to avoid contamination.

- Isolate the engine by closing the fuel supply valve.

- Clean the injector area thoroughly to prevent debris from entering the cylinder head.

- Relieve residual fuel pressure by loosening the fuel return line.

- Remove the high-pressure fuel line using two wrenches to counter-hold fittings, then cap or cover all open ports.

- Detach any electrical connections (if applicable).

- Loosen the injector hold-down clamp bolts in a gradual, even sequence to avoid stressing the housing.

- Using a suitable injector puller, extract the injector vertically to prevent scoring the bore.

- Once removed, inspect the copper sealing washer and remove it from the seat.

- Plug the injector bore to prevent contamination.

- Label components for reassembly and store injectors in clean, sealed containers for testing or service.

Marine Diesel Injectors - Removal

If you are planning to get your injectors serviced by a service company look for a company that does servicing of large commercial vehicles and trucks as they usually have quality clean work environments along with qualified and competent staff. Service companies use calibrated equipment that ensures accuracy and safety.

Cleaning injectors yourself may save some money in the immediate short term but there are significant risks damaging precision injector components, causing improper spray patterns, leaks, or injector seizure. Contamination from inadequate cleaning can lead to poor combustion or engine failure.

The most common DIY mistakes when working on diesel injectors. The main DIY steps on a boat are careful removal of the rigid fuel lines, and note that they are usually shaped to fit only one way and photographing before you dissemble is a good idea. Each line will come from the fuel pump in a specific order and will connect in accordance with the firing order. The main issues encountered when DIY are as follows:

- Poor cleanliness control: Allowing dust or debris into injector ports or fuel lines, leading to rapid injector or pump damage. Clean the engine before you start, degrease and remove all particles.

- Incorrect tool use: Using pry bars instead of proper pullers, causing bore scoring or injector body deformation. Many have to make do with spanners and other tools but use care.

- Improper torquing: Under or over-tightening hold-down bolts or fuel-line fittings, resulting in leaks, cracked clamps, or injector lift.

- Reusing sealing washer: Failing to replace copper washers, which compromises sealing and can cause blow-by or carbon buildup. Note that most injectors will come back after overhaul with ports capped and a set of new copper washers.

- Inadequate cleaning methods: Using harsh chemicals, abrasive tools, or uncalibrated ultrasonic cleaners that alter nozzle tolerances.

- Incorrect reassembly orientation: Misaligning injectors or fuel lines, affecting spray pattern and timing.

- Skipping pressure testing: Assuming an injector is clean without verifying opening pressure and spray quality. Get that pop and pattern test done. When I had mine recently done, they were all lower than spec on the pop test, and in one case the nozzle required replacement (had to be ordered from Germany) so do it properly.

Marine Diesel Injectors - Reinstallation

Prepare the injector bore. Remove any carbon deposits, clean the seat, and ensure no debris enters the cylinder.

- Install a new sealing washer. Always use a new copper washer; and verify correct orientation.

- Position the injector. Insert the injector vertically to avoid scoring the bore. Ensure alignment tabs or orientation marks match manufacturer specifications.

- Secure the hold-down clamp. Tighten bolts to the exact torque and sequence specified in the service manual to prevent leaks or injector lift.

- Reconnect high-pressure lines. Use two wrenches to avoid twisting fittings. Ensure lines are seated correctly and torque to spec.

- Reconnect return lines and electrical plugs (if applicable).

- Prime the fuel system. Bleed air using the manual lift pump or priming procedure. In some cases you might have to crack open some injector fuel line fittings to expel all the air. Note that as this might involved sustained cranking of engine, close off your seawater sea cock so as to avoid pumping seawater in and creating hydrolock situation.

- Perform leak and performance checks. Start the engine, check for fuel leaks which are usually on the high pressure side at injector connections; combustion blow-by, and smooth engine operation.

Marine Diesel Injectors Summary

Maintain absolute strict cleanliness. Never reuse sealing washers. Follow torque specifications precisely. Verify injector seating before the fuel tightening lines. Avoid over-bending or stressing the fuel lines. Injector performance is key to efficient engine performance, so do maintenance properly.