Hose Clamps Above Water Line

Hose clamps above water line and those below the waterline are critical to boat safety. A failed or poorly installed hose clamp is the difference between floating and becoming an artificial reef. In many cases they are incorrectly installed, or poor quality. Many boat sinkings occur due to detached hoses below the waterline. Properly installed hose clamps help prevent such disasters.

Ashore, hose clamps are on all those household appliances that have water systems such as the clothes washer, dishwasher and the clothes dryer as well. Then there are a multitude of hose clamps in use on the average motor vehicle as well. Anything to do with engine cooling systems has a hose clamp of some type installed

Hose Clamps Above Water Line

Let us look at these hose clamps, as actually they are the same as those below the waterline. On the average boat there are hose clamps installed on all the water systems on an engine including the exhaust hoses and fitments, as well as the engine seawater and freshwater cooling systems. Then there are hose clamps installed on through hull seacocks that connect to seawater inlets for toilets. The overboard discharges for holding tanks and toilets also have hose clamps as do sink drains. Then there are the various system overboard fittings such as bilge pumps, gray water systems and so on. Many hose-based pressurized water systems also have hose clamps installed. The worm drive hose clamp is virtually the universal method for securing flexible hoses onto hose tails of valves, pumps and so on. Hose clamps above water line are just as important as those below.

Hose Clamp Quality

Using the best quality 316 stainless steel hose clamps on everything should be a no brainer. I still run across boats with cheaper 304 stainless and even zinc electroplated plated varieties. One of the really big failings I encounter doing surveys and other repairs is the use of oversize clamps. They end up having a long tail exposed, more on that below. In some cases, such as those used on exhaust hose fittings need to be correctly sized. I found on my own boat that the clamps being used were too large and while they required the use of a socket wrench to tighten, they could not as they could not be tightened properly. The exhaust hose muffler connection had been leaking for 25 years with some water leakage and probably engine exhaust gas leakage. Choose non-perforated bands as these do not damage hoses and also provide a better seal. Also consider the widest clamp width you can do as they seal better.

Hose clamps above water line

Personally, although one clamp is sufficient on any overboard fittings above the waterline. Being the super cautious person that I am, the installation of two hose clamps is my standard. Just because the ABYC doesn’t specify it doesn’t mean you shouldn’t do it. In all applications, it's essential to use the right size clamp. You generally have to slide a hose clamp on the hose before installation. If it is too small, it will barely slide on even when opened to the maximum. A large clamp cannot be properly tensioned and the dreaded long tail will sit waiting to create mayhem later. Correctly sized clamps are essential for even tightening. The traditional Jubilee worm-drive clip is identifiable by the short and thick worm drive, which has an integral grub screw or set screw mechanism located on the band top. T-bolt hose clamps can provide increased security for mission critical systems. Double-loop hose clamps can also provide additional strength and reliability.

Hose clamps below water line

Personally, I recommend using two clamps on every fitting below the waterline. I disagree with the ABYC recommendation that calls for double clamps on just the exhaust system and fuel fill lines. Of course, the exhaust is obvious with potential for exhaust gas leakage, and having just replaced my Vetus exhaust muffler this past week found that the hose connection points do not facilitate two clamps and it was a challenge to meet this requirement. The irony was that the plastic muffler has developed a water leakage that kept filling the bilge with water due to a crack in the lower muffler exhaust connection. As a simple safety measure installing two clamps on any below waterline connection is prudent and good risk management.

Hose Clamp Installation

There are some simple things to observe when installing a hose clamp. I always lubricate the worm drive to maximize the clamping force being applied. The higher the pressure and the larger the diameter of the hose the greater the clamping force required. Always use the correct size screw driver when clamping, using incorrect screw drivers damages the slot or when undersized drivers are used you generally cannot achieve the clamping force required. I use a small socket wrench to tighten, although do not overtighten. Check that all hoses are secure and clamped properly when done, usually you can observe hoses moving on spigots so do verify movement by simple hand pressure on the hose.

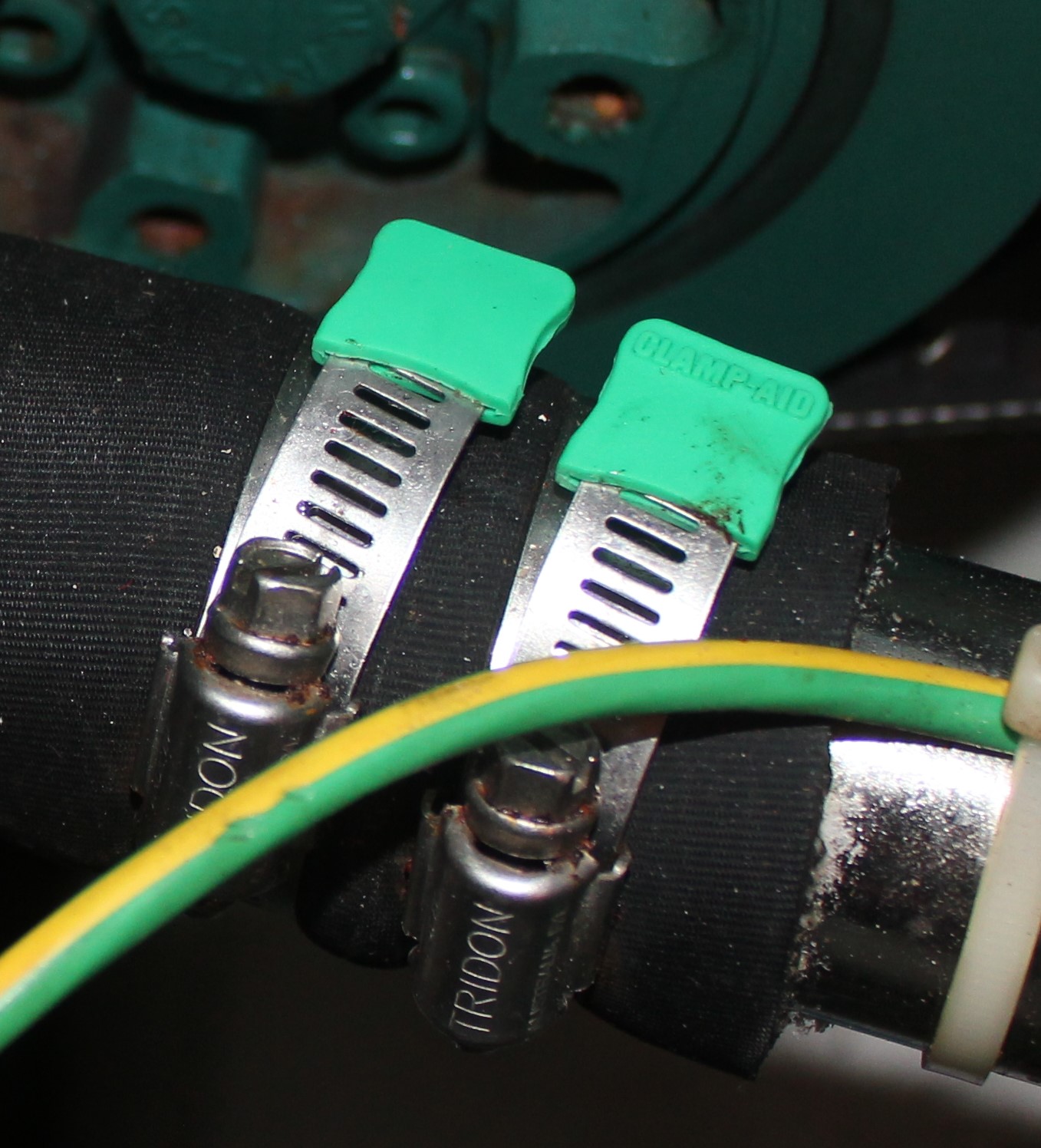

Hose Clamp Guards

An important note about using the correct sized clamps. I have frequently lacerated my hands on the long sharp tails, and on one occasion had to go to the ER to get stitched up, those tails can be scalpel sharp. When dealing with hose clamps with contaminated toilet bacteria it’s a nasty wound when it becomes septic. You can purchase small plastic hose clamp end guards or protectors from Clamp-Aid and given my past painful experiences, I absolutely recommend them. I have placed these on literally every hose clamp on my boat. A friend last week informed me about someone on the marina who had done precisely what I had and been badly lacerated on a hose clamp tail on the side of his engine. You can use color-coded ones to mark your seawater, freshwater, grey water and black water systems and so on, which is a bonus. See images of these excellent safety items on my own boat. Check out and order from your nearest Clamp-Aid reseller. Make sure your hose clamps are the right type and properly installed.