Marine Diesel Fuel System

A marine diesel fuel system reliability depends heavily on the integrity of its fuel system. For yacht owners, understanding how fuel moves from the tank to the engine and the purpose of each component in between is essential for safe operation, troubleshooting, and preventative maintenance.

Diesel engines are robust by design, but they are also sensitive to contamination, air intrusion, and fuel starvation. The following overview explains the major elements of a typical marine diesel fuel system and how they work together to ensure smooth and dependable engine performance.

Marine Diesel Fuel System - Fuel Tank

The fuel system begins at the diesel tank, typically constructed from aluminum, stainless steel, or polyethylene. Marine tanks are designed to minimize corrosion and withstand motion, temperature changes, and pressure variations. Inside the tank, several factors can influence fuel quality. Sediment from manufacturing residue or long-term use, water accumulation from condensation, biological growth, often called “diesel bug,” where microbes thrive at the fuel–water interface. Tanks include baffles to prevent sloshing, inspection ports for cleaning, and a pickup tube that draws fuel from near—but not at—the bottom to avoid ingesting settled debris.

Marine Diesel Fuel System - Pickup

The pickup tube extends into the tank and feeds fuel to the system. Many installations include an anti-siphon valve at the tank outlet. This safety device prevents uncontrolled fuel discharge in the event of a hose failure below the fuel level. It requires a small amount of suction from the fuel pump to open, ensuring fuel only flows when the engine is drawing it.

Marine Diesel Fuel System - Pre-Filters

After fuel leaves the tank, it typically passes through a primary filter/water separator, often a Racor-type unit. This is one of the most critical components in the system. The function includes coarse filtration, usually 10–30 microns, water separation through a centrifuge cone or coalescing filter, collection bowl for monitoring and draining water. Water is one of diesel’s biggest enemies; it causes microbial growth, corrosion, injector damage, and poor combustion. Yacht operators should regularly check the sight bowl for water and sediment and drain as needed. Some vessels use a dual-filter manifold, allowing the operator to switch between filters underway if one becomes clogged—an important redundancy during long voyages or rough conditions.

Marine Diesel Fuel System - Lift Pump

The next major component is the fuel lift pump, which draws fuel from the tank side of the system and pushes it toward the engine. Older engines may use mechanical lift pumps driven by the camshaft, while modern engines typically use electric pumps.

Primary functions are to maintain stable suction and supply pressure, move fuel through filters and towards the injection pump, prime the system after filter changes. Electric pumps often incorporate priming capability, allowing operators to remove air from the lines without manual bleeding.

Marine Diesel Fuel System - Fuel Filter

Once fuel reaches the engine, it passes through the secondary filter, usually a fine 2–10 micron filter mounted on the engine block. Its purpose is to remove microscopic contaminants that could damage the high-precision components of the fuel injection system. Diesel injection pressures can exceed 20,000 psi in common-rail systems, so even tiny debris can cause injector wear or failure. This filter is the final line of defense before the fuel injection system.

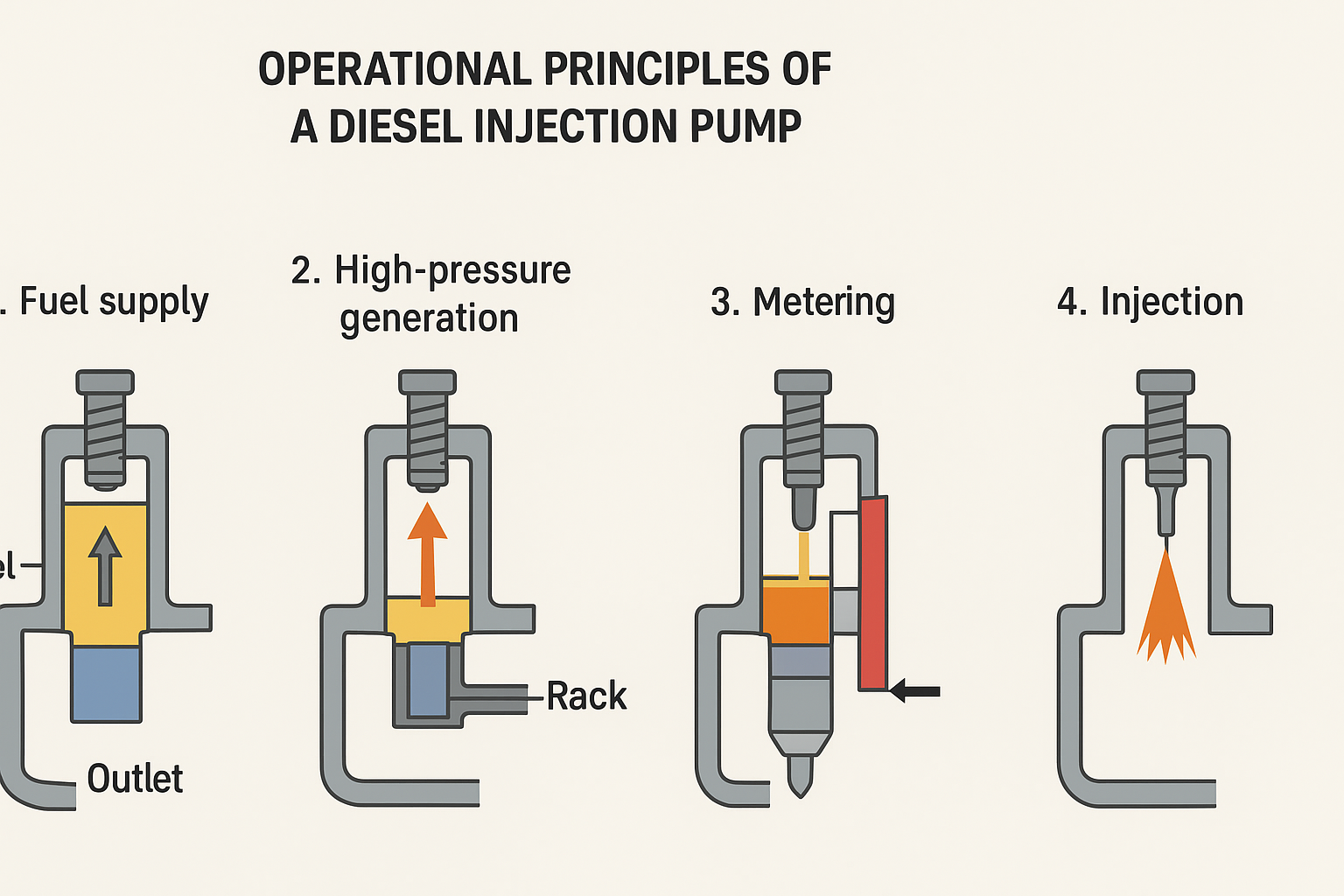

Marine Diesel Fuel System - Fuel Pump

The fuel injection pump (or high-pressure pump in common-rail systems) pressurizes the fuel and meters it precisely for combustion. Two major types are found on yachts. Mechanical injection pumps (inline or rotary): Control fuel delivery mechanically in synchronization with engine speed. Common-rail high-pressure pumps: Maintain constant rail pressure while electronic control units (ECUs) manage individual injector timing and volume. Regardless of type, these pumps demand exceptionally clean fuel and stable pressure; otherwise, the engine may experience hard starting, rough running, or power loss.

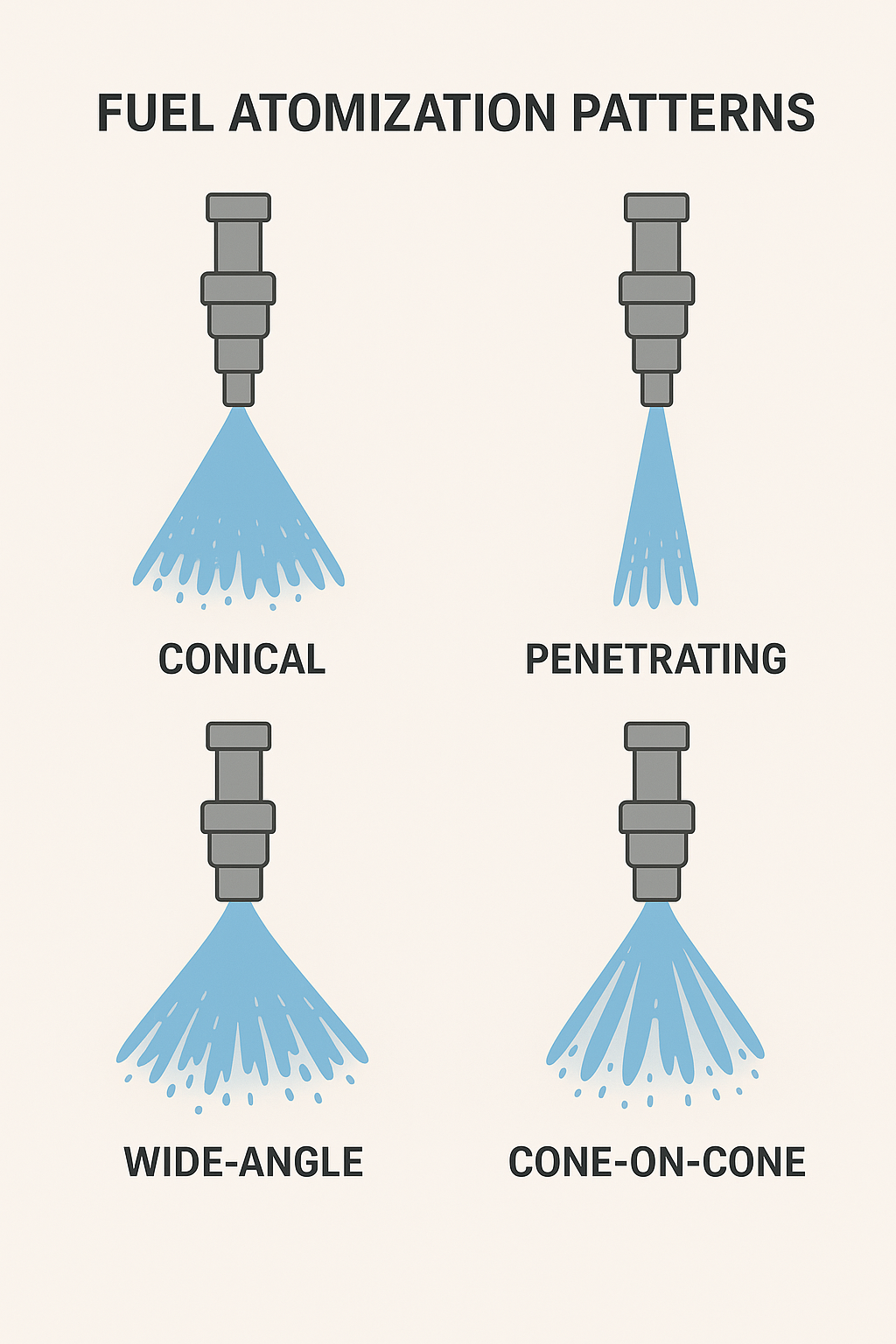

Marine Diesel Fuel System - Injectors

Injectors are responsible for delivering fuel directly into the combustion chamber at extremely high pressure and in a finely atomized spray pattern. Poor atomization leads to incomplete combustion, excess smoke, and reduced efficiency. Common failure indicators include black exhaust smoke, uneven idle, elevated fuel consumption, difficulty starting. Because injectors operate at high precision, contamination or water in the fuel system can quickly cause damage.

Marine Diesel Fuel System - Return Line

Marine diesel engines circulate far more fuel than they consume. Excess fuel is routed back to the tank through the fuel return line, which helps cool the injectors and reduce vapor buildup. Yacht owners should be aware that return fuel also carries heat, if the tank is small or the engine runs hard for long periods, fuel temperature may increase. Some systems incorporate a fuel cooler in the return loop to maintain optimal temperatures.

Marine Diesel Fuel System -Vent & Filler

The fuel vent allows air to escape the tank during filling and re-enter as fuel is consumed. A blocked vent can cause fuel starvation, tank deformation, or fuel spray during refueling. Regular inspections ensure screens and vent loops are clear. The fill pipe needs to be secure, properly grounded, and designed to prevent seawater intrusion.

Marine Diesel Fuel System - Best Practices

Use high-quality diesel, ideally with low sulfur and additives that enhance lubrication. Like many I avoid bunker barges and marina pontoon stations. Keep tanks full when the yacht is idle or laid up to reduce condensation. Drain water separators frequently, you should check daily when underway in remote cruising areas. Replace filters according to manufacturer intervals or sooner if contamination is suspected. Avoid disturbing sediment by careful refuelling and minimizing tank agitation when possible. Monitor for air leaks, especially after maintenance, as even small leaks that can cause engine shutdowns. Schedule tank cleaning every few years, particularly for vessels stored for long periods or operating in warm climates. All you need to know about boat diesel fuel systems.