How Does Boat Engine Work

How does boat engine work? Diesel engines are renowned for their durability, fuel efficiency, and ability to produce high torque at low RPM. Unlike gasoline engines, which rely on external spark ignition, diesel engines depend entirely on heat generated by compression to ignite the air–fuel mixture. Understanding how a diesel engine operates requires examining the process from the moment the operator engages the preheat circuit to the completion of the engine’s thermodynamic cycles. This article provides a detailed, step-by-step explanation of these events.

Marine diesel engines sit at the center of most cruising sailboats, providing reliable power for maneuvering harbors, charging batteries, and keeping life aboard comfortable when the wind fades. More than just propulsion, they support refrigeration, navigation systems, and essential onboard services that modern cruisers depend on. Known for durability and fuel efficiency, marine diesels are built to handle long hours, varied conditions, and the demands of extended cruising. Understanding the basics of care, troubleshooting, and system integration helps sailors stay confident and self‑sufficient wherever their passages lead.

How Does Boat Engine Work

1. Preheating: Preparing the Combustion Chamber. When the operator turns on the preheat switch (often called the glow plug or heater plug switch), electrical current is delivered to small heating elements called glow plugs that are located within each cylinder’s pre-combustion or swirl chamber. The purpose of these glow plugs is not to ignite fuel directly but to warm the air and combustion surfaces inside the chamber.

How Does Boat Engine Work

Diesel engines operate on the principle of high compression ratios, typically between 16:1 and 22:1. At low temperatures, especially in cold climates, compressed air may not reach the auto-ignition temperature of diesel fuel (~210°C). Cold metal cylinder walls also absorb heat, making ignition more difficult. Glow plugs counter these effects by elevating the initial temperature so that once fuel is injected, it can vaporize and combust efficiently. In modern common-rail engines, electronic control units (ECUs) may continue operating the glow plugs even after the engine starts to ensure stable combustion until normal thermal conditions are achieved.

How Does Boat Engine Work - Cranking

After sufficient preheating, usually 5-10 seconds, the operator engages the starter motor. The starter motor draws high current from the battery and rotates the flywheel, which in turn spins the crankshaft. Through connecting rods, the crankshaft drives each piston through its cycles. During cranking, the engine is not yet firing on fuel power. All rotational motion is supplied by the electric starter. The key objectives during cranking are to draw air into the cylinders, compress that air to generate heat and allow the fuel injection system to pressurize and deliver fuel. At this stage, the injection pump (mechanical or high-pressure common-rail pump) begins building fuel pressure. Once the control system detects adequate speed and pressure, typically around 150 to 250 RPM, fuel is delivered into the cylinders near the top of the compression stroke.

How Does Boat Engine Work - Ignition

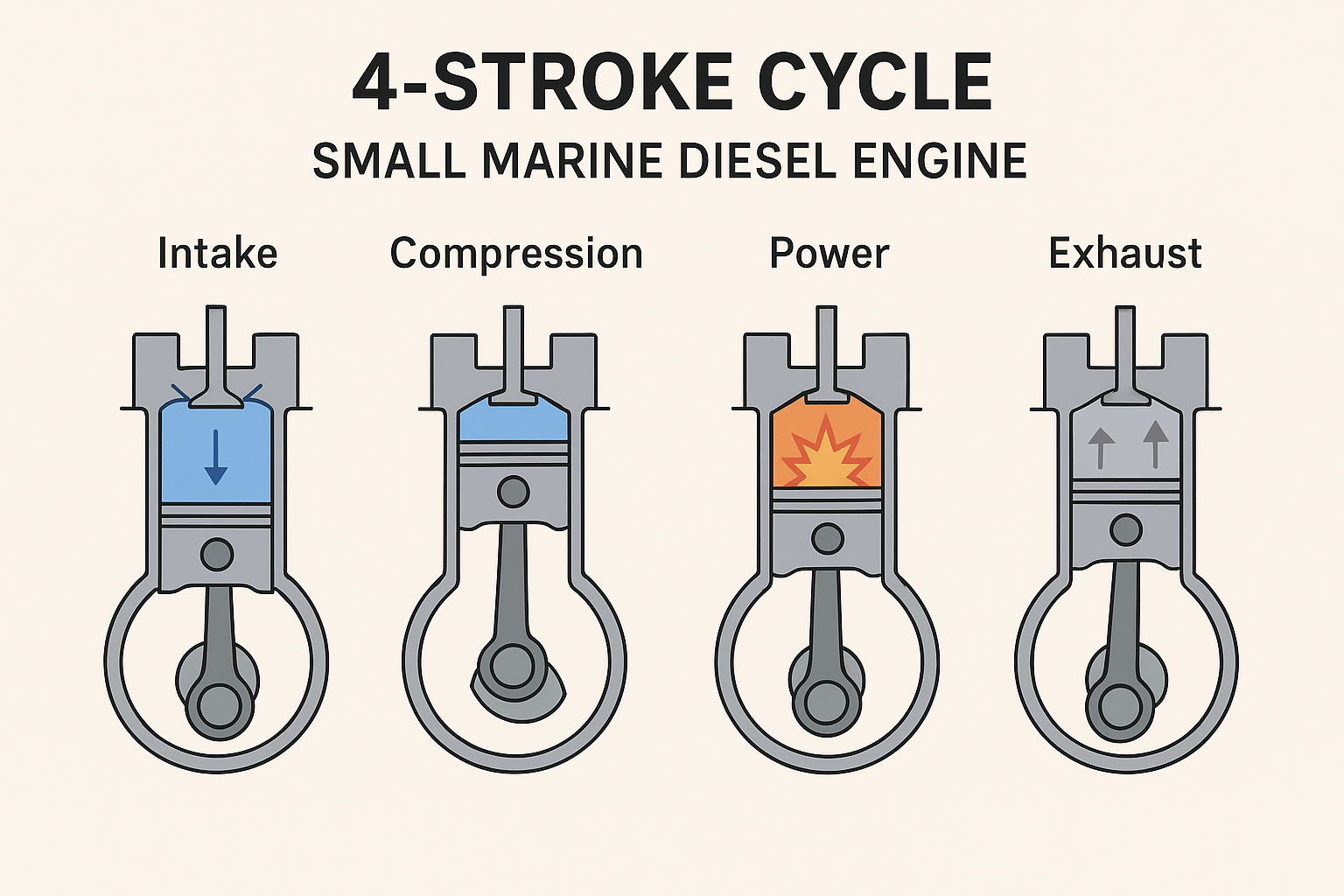

As the engine turns over, each piston moves through its four-stroke cycle. Importantly, diesel ignition begins with the compression stroke:

Intake stroke: The intake valve opens, and fresh air is drawn into the cylinder as the piston moves downward. No fuel is introduced during this stroke.

Compression stroke: The intake valve closes, and the piston moves upward, rapidly compressing the air. The temperature rises dramatically—often exceeding 500°C.

Fuel injection and ignition: Near the end of the compression stroke (Top Dead Center, or TDC), pressurized diesel fuel is sprayed into the hot compressed air. The fuel atomizes, vaporizes, and spontaneously ignites.

This moment of self-ignition is what distinguishes diesel engines from spark-ignition engines. With the first few successful combustion events, engine speed increases. Once the rotational inertia of the crankshaft and flywheel is sufficient, the engine becomes self-sustaining, and the ECU or mechanical governor transitions from cranking mode to normal running operations. The starter motor disengages via the starter solenoid.

How Does Boat Engine Work - Cycles

Once running, the diesel engine repeats its four-stroke operating cycle continuously:

1. Intake Stroke

The piston moves downward from TDC with the intake valve open. Fresh filtered air is drawn into the cylinder. Turbocharged engines compress this incoming air using exhaust-driven turbines, increasing oxygen availability and improving power output and efficiency.

2. Compression Stroke

The intake valve closes, and the piston rises. Because no fuel–air mixture exists (only air), very high compression ratios can be achieved without detonation risk. The air temperature rises well above the auto-ignition point of diesel fuel.

3. Power (Combustion) Stroke

Fuel is injected at extremely high pressure, anywhere from 10,000 psi in older engines to more than 35,000 psi in modern common-rail systems. Multiple injection events may occur:

Pilot injection: small pre-charge to reduce noise and smooth combustion

Main injection: primary fuel delivery producing the main power output

Post-injection: emissions control, particulate reduction, or aftertreatment support

The fuel ignites almost immediately upon mixing with the hot compressed air, creating rapid gas expansion that forces the piston downward. This is the power-producing stroke.

4. Exhaust Stroke

After the power stroke, the exhaust valve opens, and the piston rises back to TDC, expelling combustion gases. These gases flow through the exhaust manifold and turbocharger turbine (if equipped), transferring energy to the turbocharger before being released through the exhaust system.

How Does Boat Engine Work - Engine Control

Modern diesel engines rely heavily on electronic control units to manage fuel delivery, injection timing, boost pressure, and emissions systems. Key factors enabling efficient operation include:

Precise injection timing: Ensures fuel is delivered just before TDC

Atomization quality: Finer droplets improve combustion efficiency

Turbocharging and intercooling: More dense air increases power and reduces fuel consumption

Mechanically governed engines achieve control through mechanical linkages and timing devices, though with less precision than their electronic counterparts.

How Does Boat Engine Work - Summary

From the moment the preheat switch is activated to the continuous repetition of the four-stroke combustion cycle, diesel engines operate through tightly coordinated mechanical and thermodynamic processes. Their reliance on compression ignition, high-pressure fuel injection, and robust construction enables high torque output, durability, and efficiency. Understanding these operations reveals why diesel powerplants remain dominant in heavy-duty applications such as boats. Do you know how a boat engine works? Why not learn.